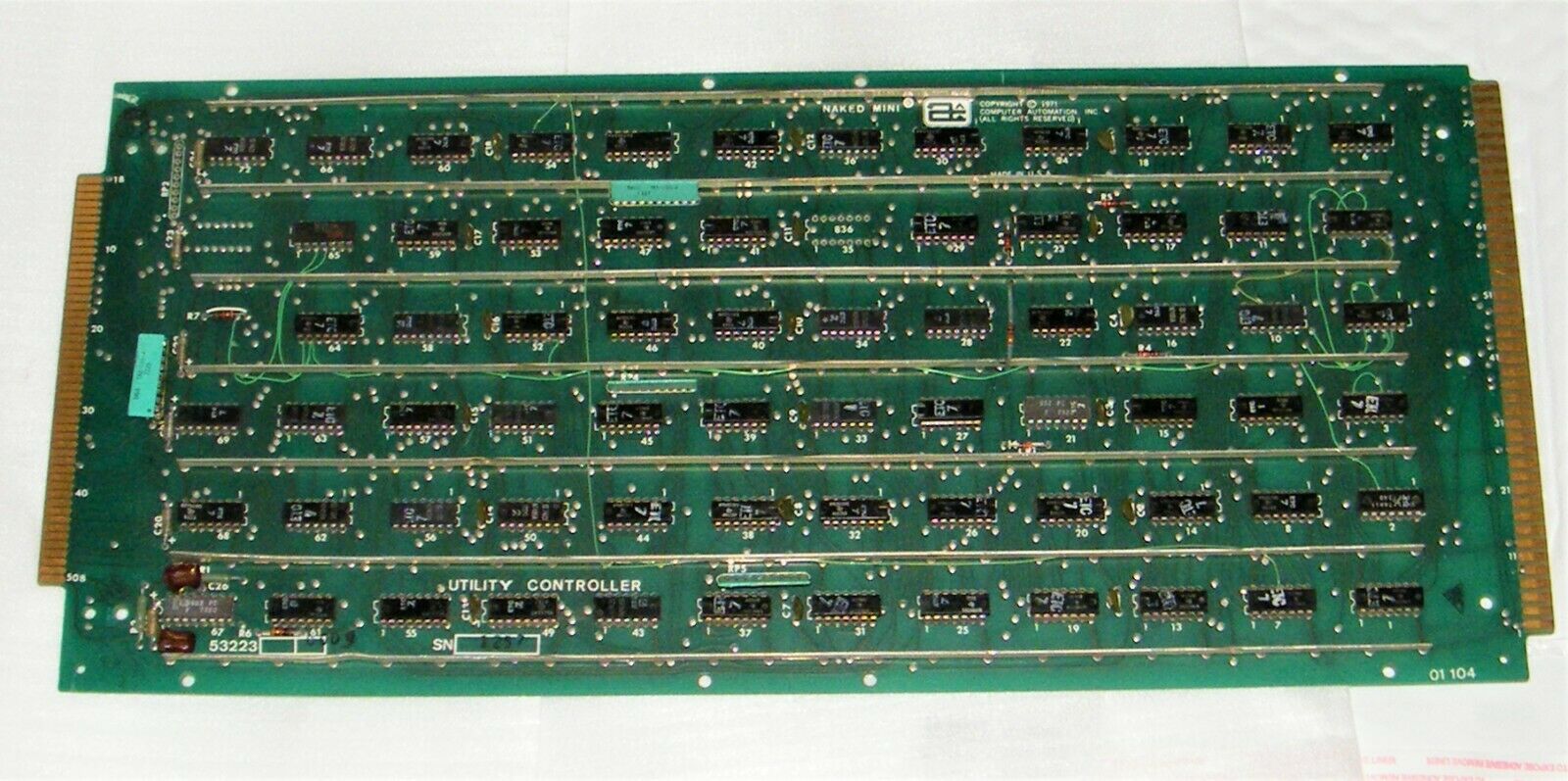

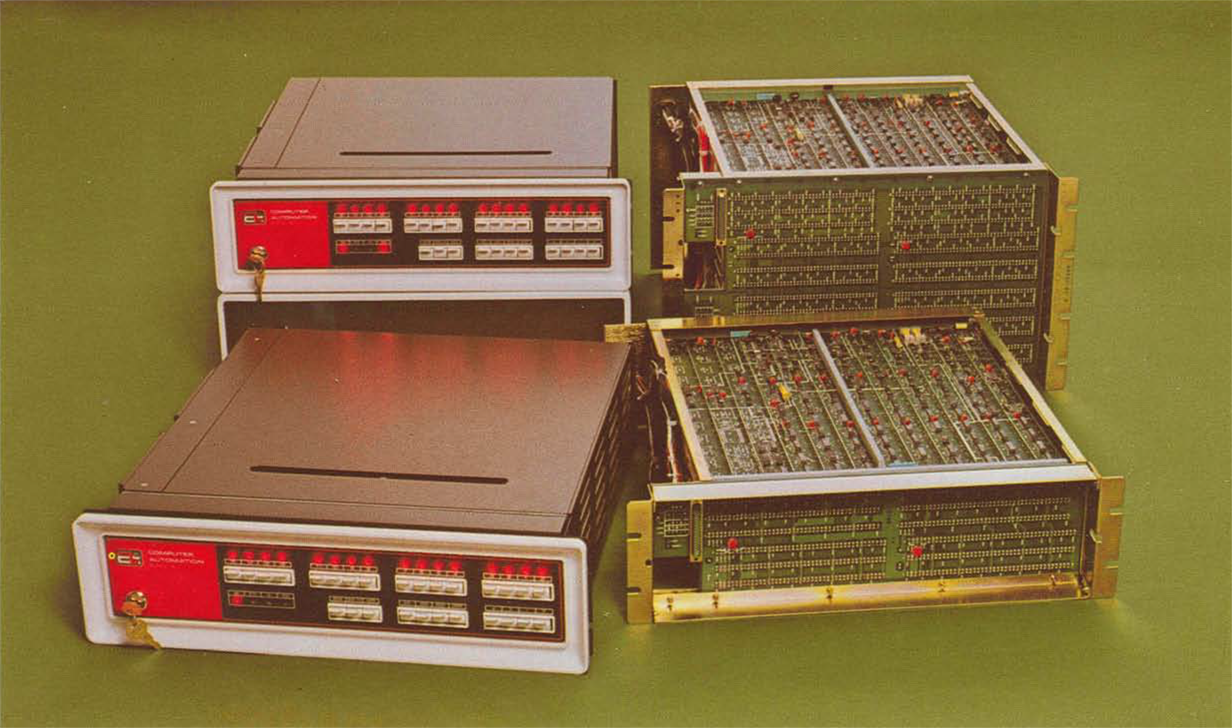

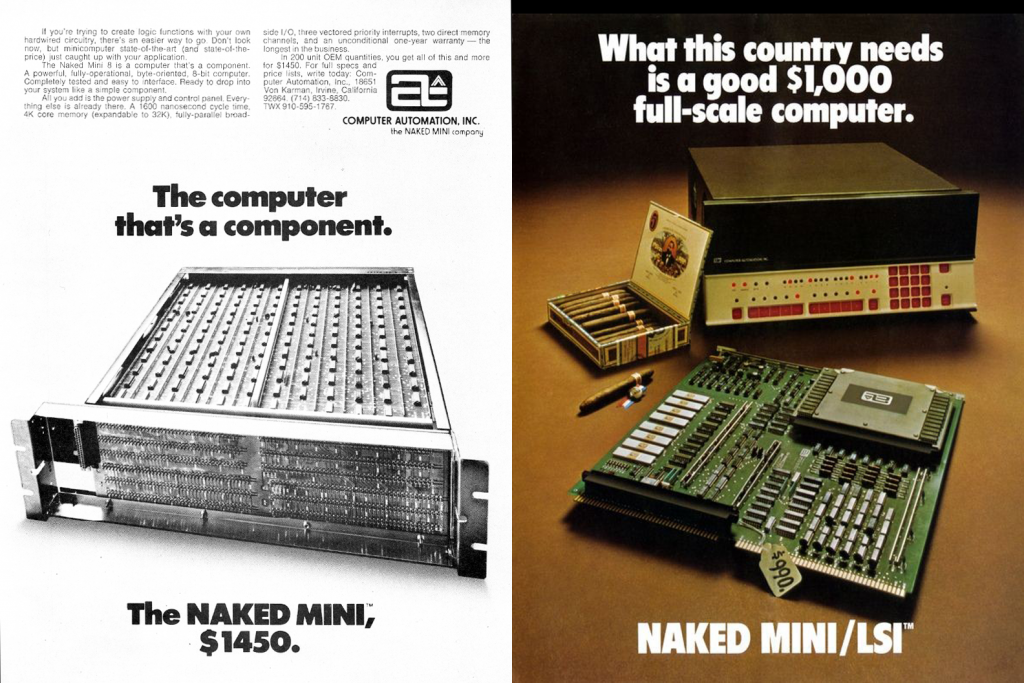

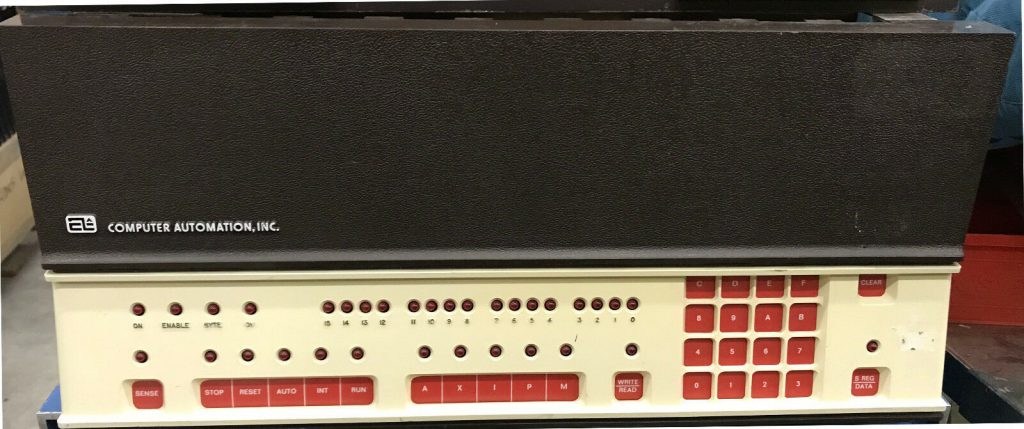

Since August, 2019, when I purchased a Computer Automation Alpha LSI-2 minicomputer on eBay.com, I have been scouring the internet for information, hardware, and software for the almost forgotten Computer Automation “Naked Mini” Alpha 16 and Alpha/LSI-2 minicomputers from the first computer revolution in the mid-1970’s.

Restoring a 44 year old minicomputer is not for the fainthearted. First, you need to realize that my particular choice for restoration is not the easiest target. Computer Automation has been out of business since 1992. Even though Alpha LSI mini’s were manufactured for nearly 10 years, and tens of thousands were sold, they were mostly used as “components” in other products, and were not well known as stand-alone minicomputers.

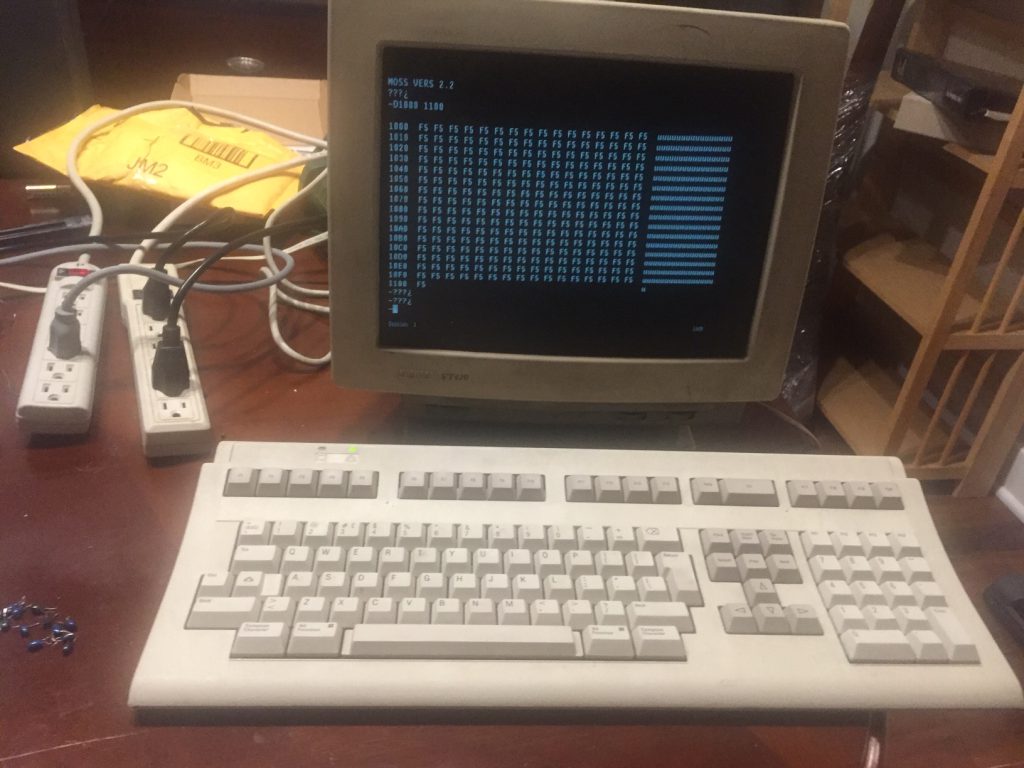

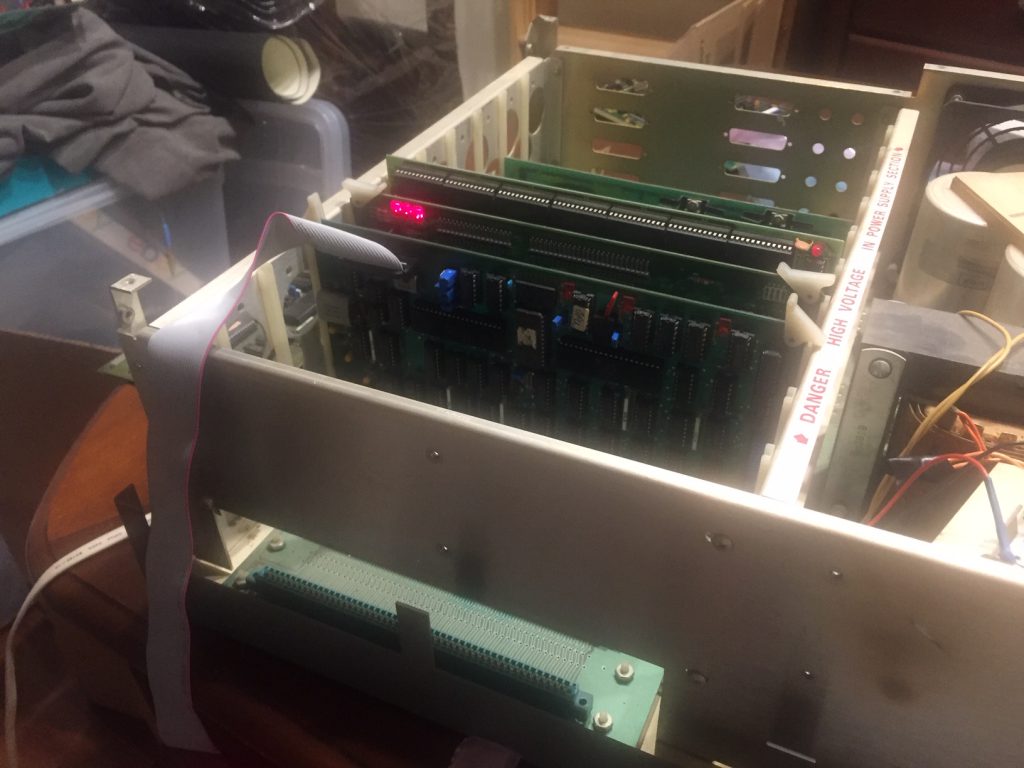

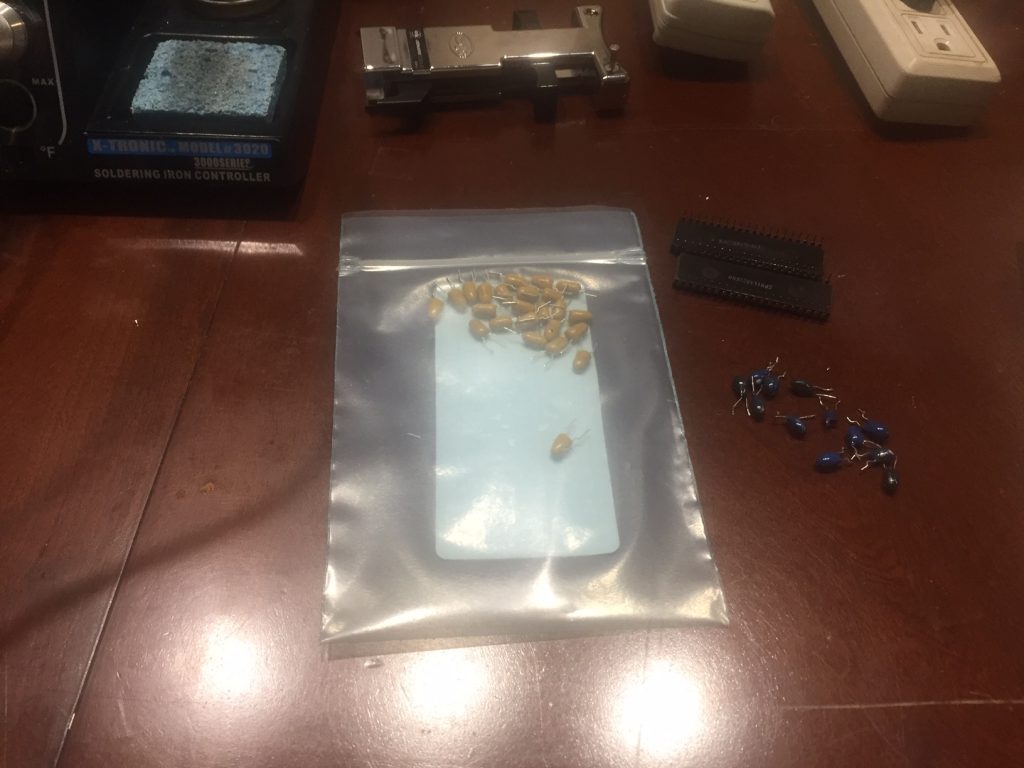

It all started with Beginnings…